About

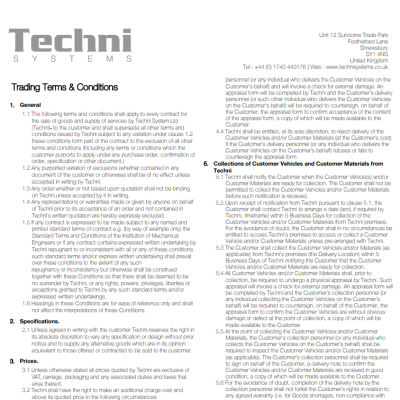

Techni Systems are leaders in offering vehicle mounted mobile air compressor systems. Our success comes from the uniquely engineered technology that integrates the compressor onto the vehicle's engine, electronic control systems and market leading warranty.

Delivering up to a constant 70cfm* and up to 175psi. The Techni Systems VR70 is the most powerful engine mounted belt driven compressor available. You will be faster and more efficient with your Techni VMAC mobile compressed air system.

Techni Systems and VMAC have over 100 years combined collective knowledge, experience and direct vehicle manufacturer relationships to allow us to efficiently provide a superior design, analysis and fully engineered compressor mount and drive solutions. Accurate physical measurement, 3D parametric computer aided design, FEA validation, 3D printing, test fitting, pattern tooling, unique in-house CNC machining. ISO 9001-2015 accredited, our quality system ensures from design, CMM inspection, batch, process control through to delivery we strive to offer the best.

* Vehicle dependant

COMPACT

POWERFUL

LIGHTWEIGHT

MEET THE TEAM

Lynsay Doel

Director

Philip Doel

Director

Charlotte Doel

Commercial Operations Manager

Francesca Doel

Commercial Operations Manager

Ben Watts

Sales Manager

Alice Bevan-Fisher

Supply Chain Manager

Ross Rogers

Manufactoring Manager

Julia Evola

Finance Manager

Steve Richards

Aftersales Manager

Andrew Bailey

Design & Development Manager

Charlotte Haden

Sales & Marketing Office Manager

Connor Roberts

Executive Assistant

Ian Mapp

Key Account Executive

Clare Watkins

Key Account Executive

Carl Evans

Marketing Executive

Ben Mancini

Key Account Executive

Jordie Taylor

Sales Executive

Jessica Horne

Key Account Executive

Tom Harris

Sales Administrator

Adam White

Design Engineer

Richard Boyles

Design Engineer

Phil Smith

Design & Development Engineer

Sam Osman

Project Manager

Janos Barany

Head of Technical

Hayley Wells

Workshop Controller

Steve Hopkins

Product Technician

Adrian Falat

Senior Product Technician

Stephen Jarrett

Product Technician (Conversion)

AKSEL KAROLCZAK

Engineering Apprentice

BEN PRITCHARD

Product Technician

Lewys Rees

Product Technician

Jordon Codd

Product Technician

Sally Chinn

Supply Chain Continuous Improvement Officer

Dave Morris-Jones

Supply Chain Coordinator

Patryk Falat

Supply Chain Coordinator

Katrine Brown

Financial Assistant

Claire Price

Financial Assistant

Adam Jones

Warehouse Team Leader

Michael Crighton-White

Warehouse Operative

Caroline Evans

Goods in & Quality Inspector

Craig Brisbourne

Goods In & Quality Inspector

Daniel Pryce

Warehouse Operative

Callum Stickley

Warehouse Operative

JACK CRIGHTON-WHITE

Warehouse Operative

Joanna Falat

Warehouse Operative

Liam Brown

Warehouse Operative

Arun Mccarroll

Warehouse Operative

MARCO ROSSONI

Techni SL Warehouse Operative

PATRICIA DE JUAN

Techni SL Warehouse Administrator

John Taylor

CNC Shift Team Leader

STUART INWOOD

CNC Shift Team Leader

Carl Brunton

CNC Operator / Setter

Dave Williams

CNC Operator / Setter / Programmer

Peter Standen

CNC Operator

Phil Coyle

CNC Operator / Setter / Programmer

BEN GARDNER

CNC Operator

Dylan Cartlidge

Quality Assurance Engineer / CMM Programmer

CHARLIE MCEWAN

Quality Apprentice

James Mitchell

Sales Executive US

Janorra Love

Techni LLC Sales Administrator

Kevin Glassing

Techni LLC Sales and Warranty Administrator

Jarrek Montgomery

Techni LLC Sales Administrator

Shannon Doel

Techni LLC General Manager

ROBERT LOVE

Techni LLC Warehouse Operative

Paul Sanders

Design Engineer

Miriam Claros

Techni LLC Warehouse Operative

Amber Scott

Techni LLC Head of Accounts

Quality Management

QUALITY POLICY STATEMENT

Techni Limited is a customer focused organisation, committed to the ownership and continual improvement of its Processes and the Quality System. We have adopted a process approach when developing our quality system, and recognise that process outputs become inputs to follow-on processes. This policy statement and the quality management system were developed following a review process conducted by top management which considered the context of the organisation. We have also recognised risks and opportunities that must be addressed within the agreed context of the organisation, and have developed a risk-based approach to decision making regarding these risks and opportunities.

We constantly monitor our ability to supply products and services that consistently meet customer and applicable requirements, and satisfy this via setting objectives and targeted measures for our core processes, supported by management review and auditing.

We have recognised internal and external influences, and apply the following principles:

- The need to maximise customer satisfaction and build long term relationships.

- To only accept contracts for which we have the ability and expertise to satisfy.

- To operate in an ethical and efficient manner, providing a sufficient return on investment.

- To provide a suitable and safe working environment, where all employees are considered to perform an important role, and be a member of the team.

- Provide an environment where employees can maximise their potential, and are encouraged to support and help others.

- To form long term and mutually beneficial relationships with key suppliers.

- To provide local employment opportunities.

- To minimise any adverse environmental impact.

The management team provide leadership to create and maintain an environment which encourages the fulfilment of quality objectives which must include those related to customer satisfaction. They have responsibility for ensuring that the quality policy is understood, implemented, and complied with. The Quality Manual defines quality policy and how the requirements of ISO 9001:2015 have been addressed. All personnel are responsible for ensuring that each part of the quality system relevant to them, is operated in accordance with specified requirements. This policy will be issued to all relevant interested parties upon request.

Click here to download a copy of Techni’s ISO 9001:2015 Certificate

Click here to download a copy of Techni’s ISO 9001:2015 Certificate

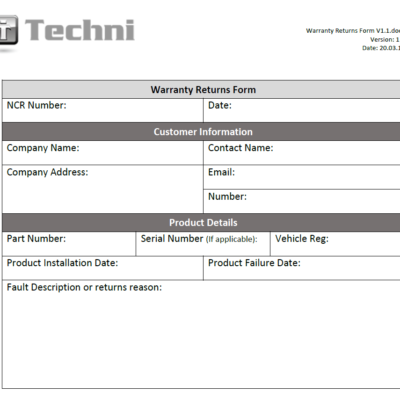

Downloads

Product Brochures

Service and Warranty

Quality Documents

Terms and Conditions

Careers

Training and knowledge are the cornerstones of any successful business. Here at Techni we put development and investment in our employees high on our agenda. This applies to everyone, from the most junior apprentice to the most senior Manager or Director.

We operate in an increasingly competitive marketplace and it is essential that we continue to invest heavily in the training of all our staff. This ensures we have the best candidates to take Techni forward and that we offer everyone a clear path to progress and develop their personal careers.

Techni is an equal opportunities employer. As such at Techni every employee has a ‘hands-on’ role and important part to play in the delivery of a high-quality service to all of our customers. In doing so, everyone is in a position to add value to the company, contribute positively to its continued growth and maintain its respected position within the vehicle conversions industry.

Techni is committed to maintaining free and open communications among its employees in every area of the business and at every level. Discussion, ideas, and suggestions are actively encouraged and regarded as essential to the company’s future, development, and continuous improvement.